SIH chimney liners are formed from the finest raw materials, blended in a unique formula to give a unique combination of temperature resistance and strength, as well as exceeding the European Standards for chimney products.

The SIH is a durable product due to its chimney pipe column. The chimney meets the requirements of fire resistance class F90 and LA90. Thus, in the event of a standard fire, the SIH retains its function for a duration of 90 minutes and thus meets many building code requirements.

A cost effective way of building a chimney in a home, therefore reducing the need for gas and electric, due to high charges, as well as being a superb focal point and a heating source during any power cuts.

All gas, oil, solid fuels and biomass fuels.

Open fire heating

Recessed stoves

Freestanding stoves

Construction begins by providing a suitable foundation and constructional hearth in accordance with local Building Regulations and site requirements.

Form the fire opening onto the constructional hearth. 100mm of brick or blockwork must be built around the sides and back of the firechest to comply with Building Regulations.

Apply Schiedel Rapid HT Cement onto a suitably formed fire gather. Position the flue liner onto the prefabricated gather, female rebate facing upwards. Arrows on each flue liner indicate the directional flow of flue gases. Continue to apply Schiedel Rapid HT Cement to each flue liner, cleaning any access material from the joints.

A suitable cast-in-situ concrete slab lintel must be provided above the fireplace recess. Alternatively you could use suitable pre stressed lintels, for this method a support plate is required under the support block. It is recommended to have a minimum of 600mm length of flue pipe before connecting to the chimney.

The support block is bedded onto the slab lintel using weak mix mortar. A stainless steel adaptor or a section of Prima Smooth connecting flue pipe is used to connect from the support block to the stove flue pipe. This adaptor is pushed up onto the support block spigot (fibre rope should be used to create a seal).

Apply Schiedel Rapid HT Cement onto a suitably formed fire gather. Position the flue liner onto the prefabricated gather, female rebate facing upwards. Arrows on each flue

liner indicate the directional flow of flue gases. Continue to apply Schiedel Rapid HT Cement to each flue liner, cleaning any access material from the joints. The support block is bedded onto the slab lintel using weak mix mortar. A stainless steel adaptor or a section of Prima Smooth connecting flue pipe is used to connect from the support block to the stove flue pipe. This adaptor is pushed up onto the support block spigot (fibre rope should be used to create a seal).

A soot door must be provided below the flue pipe entry to allow for inspection and removal of soot and debris. A suitable wall sleeve is to be used to seal the cavity wall. Any combustible insulation within the wall must be kept away from the single skin connecting flue pipe by at least 1.5 x its diameter. (Example: diameter 150mm x 1.5 = 225mm distance).

The flue pipe is a push fit over the spigot on the adaptor. Seal off the gap between the flue pipe and wall sleeve with fire proof rope and closing plate.

SIH chimney liners are formed from the finest raw materials, blended in a unique formula to give a unique combination of temperature resistance and strength, as well as exceeding the European Standards for chimney products.

The SIH is a durable product due to its chimney pipe column. The chimney meets the requirements of fire resistance class F90 and LA90. Thus, in the event of a standard fire, the SIH retains its function for a duration of 90 minutes and thus meets many building code requirements.

A common issue is that many newly built chimneys rely on steel liners to allow a stove installation, because the typically 225mm clay/concrete system specified has too wide a diameter for the appliance.

Schiedel Chimney Systems Isokern and ceramic liners start at 150mm and 160mm diameters respectively, removing the need to install an extra liner, saving both time and money.

| Application | |

Flue gas temperature (dry) |

≤ 400 °C |

Material (Inner liner) |

Ceramics |

Material (Insulation) |

Mineral fibre |

Material (Outer case) |

Lightweight concrete |

Thermal resistance by insulation thickness |

0,465 m²K/W |

| General product features | |

Performance features |

T400 N1 D3 G50, T400 N1 W2 O50 |

Operating |

Negative pressure (N) |

Room sealed |

Yes |

Occupation |

Single |

Suitable for passive house |

No |

Heating technology |

Low temperature technology, Conventional heating technology |

Notes |

The implementation of room air independence is only possible through an annular gap or an adjacent shaft. |

Helpful sections for chimney installers

A set of training courses at our centre in Washington, Tyne & Wear.

We're available to discuss the technical aspects of our product range.

Helpful sections for chimney installers

3D modelling object available for download.

We're available to discuss the technical aspects of our product range.

Helpful sections for chimney installers

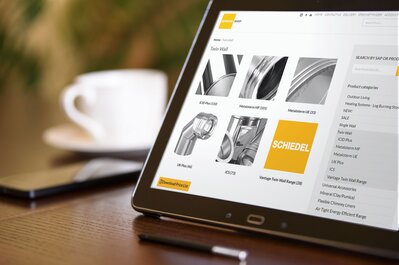

Products available to purchase, as well as full information on our range.

Apps designed for seeing how our stoves and outdoor appliance look like in your homes and gardens, using the latest technology. We also have our excellent stove and chimney installation app, which has all the technical information and guides for installing our systems.

This App allows the user to see what a wood burning stove looks like in a room, as well as calculating the components required.

Simply point and see – it’s as simple as that with our new AR Outdoor Fireplace Designer.

This app was designed for installers to have all the information they require in a few quick clicks.